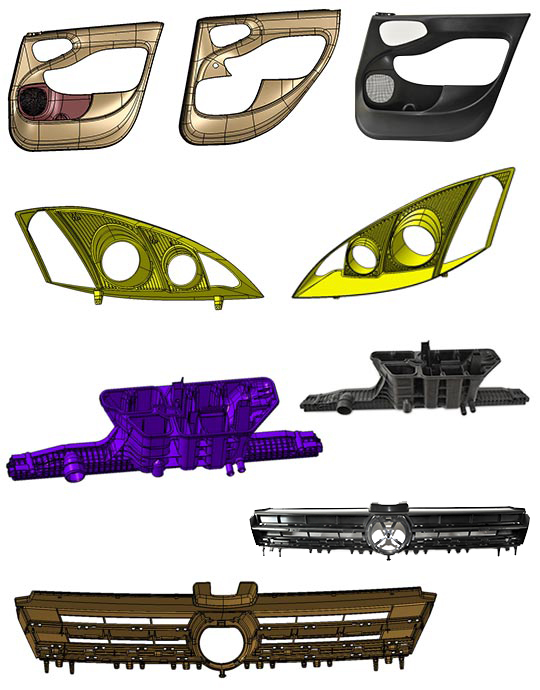

Mould Design

Moritz Project is the ideal partner for the design of plastic molds and it has contributed to the realization of some of the most famous models of the main world automotive manufacturers.

The experience and the designers’ abilities allow the customer to be assisted in the various steps of the production:

- Co-design: the client with an idea can find at Moritz Project everything that is needed to turn it into reality, from the 3D design to the implementation;

- Study and industrialization of the product: it is not always possible to produce the designed idea the way it was originally thought. This is the reason why our technicians can identify possible problems and offer effective solutions.

- Mold flow analysis: this type of analysis is made with a software for the simulation of the injection molding of the plastic parts, which allows to optimize both the product and its mold. The mold flow analysis permits to identify all the problems such as the weld lines of the materials, hot spots, number of injection points necessary to fill the piece.

Moritz Project is the perfect partner also for its ability to realize all different kinds of molds, from traditional to stack molds, from cube injection molds to 2k injection molds with blades or rotation tool. The study also realizes processing based on specific requests made by clients on patents or proprietary technology with confidentiality obligations.

Contact us for more information.